Brand Name: VRcooler

Model Number: OEM

Place of Origin: Jiangsu, China (Mainland)

NH3 heat exchanger coil

Industrial Cooler

Small to Medium Industrial and Process Room Applications (2-34 Ammonia Tons)

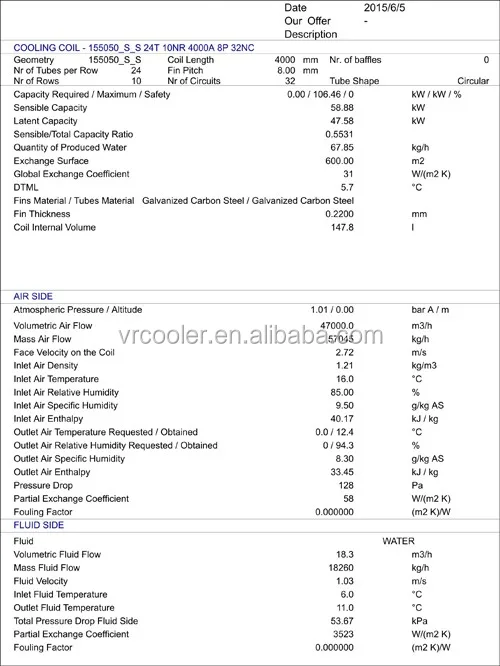

Coil Design We have coil design software which Guentner and Cabero are using, Vrcooler offers tailor-made heating and cooling unit.

Tubes Standard tubes are 5/8", 1/2” OD, 304, 316 stainless steel, hot dip galvanized steel or aluminum. Tubes are arranged inline in the direction of airflow for maximum heat transfer with minimum airside pressure drop.

Tubes are expanded into the fin collars to ensure maximum heat transfer between tube and fin. After welding, entire coil is leak tested at 500 psig with dry air under water.

Fins Standard fin material is aluminum 1100 alloy. Fins are continuous plate type with full length, self spacing collars. Fins are die-formed into a corrugated (waffle) configuration to encourage turbulent airflow and improve heat transfer efficiency. Fins are available in standard fin spacings of 3, 4 or 6 fins per inch.

Cabinet Standard cabinet/casing material is corrosion resistant galvanized steel. Fans are individually compartmented with continuous tube sheets to permit fan cycling. AIl evaporators may be ceiling or floor mounted. Units ship with integrated hangers, removable legs, and forklift brackets attached.

Fans and Motors: Direct-drive, high efficiency fans are selected and installed to maximize coil performance. AIl evaporators utilize 24", 26" and 30" composite, adjustable pitch fans. Standard motors are 1140 rpm, 3 Phase, 60 Hz motors with TEAO/ATO (Totally Enclosed Air Over with Automatic Thermal Overload Protection) in standard NEMA frame sizes. Motors are available in 1/3, 1/2, 3/4 and 1 HP.

Circuiting: Standard evaporators are suitable for pumped ammonia systems. AIl evaporators are individually circuited for specific applications to ensure optimum efficiency.

Drain Pan: AIl evaporators feature a hinged drain pan made from welded heavy gauge aluminum. The drain pan is corrosion resistant, light weight and provides adequate heat conductance for pan defrost. The drain pan features oversized connections and is sloped towards the connection to ensure complete drainage. Insulated drain pan covers are required by the USDA for some applications and are standard on AIl evaporators.

Defrost System In applications where frost buildup on the coil can be expected and/or the coil block cannot be defrosted by room air, an optional defrost system is required. AIl evaporators may be manufactured with hot gas, electric, water or hot gas/electric defrost systems.

Hot Gas Defrost: Hot gas is circulated through the coil block as a medium to heat and defrost the coil. In addition, hot gas may be circulated through tubing attached to the bottom of the drain pan resulting in efficient pan heating/drainage. All connections are made within the boundaries of the extended drain pan which ensure containment of condensate drip. Hot gas tubing is mounted within the insulated drain pan cover.

Electric Defrost: Heater elements are evenly distributed throughout the coil block to provide complete defrost. In addition, heater elements may be placed and mounted inside the drain pan to prevent ice buildup and promote drainage. Electrical connections are made in a non condensing location and all elements are fully removable and/or replaceable.

Water Defrost: Water is flooded over coil surface and collected within the drain pan. A removable water distribution pan is placed over the coil block, which evenly distributes water over finned surfaces. A fold out guard is used to capture any splash outside the drain pan.

Optional Features

Coil defrost - hot gas, electric or water

Heated drain pan - hot gas or electric

Stainless steel or aluminum cabinet

Header/return bend end covers

Variable fin spacing for heavy frost conditions

Corrosion resistant fin coatings

Other motor options (low speed, high speed, 50 Hz, etc.)

Variable speed fan control

Other cooling mediums/systems (glycol mixtures, NH3 DX, halocarbon DX/pumped)

We have heat exchanger design software, Vrcooler offers tailor-made heating and cooling unit.

| Low Temperature Blast Freezing |

| Blast Freezing Tunnels and Rooms |

| Low Temperature Test Chambers |

| Low Temperature Refrigerated Ships Holds (Marine) |

| Low temperature blast freezing |

| Blast chilling |

| Carcass cooling |

| Cold stores |

| Chill stores |

| Spiral Chillers |

| Spiral Freezers |

| IQF Tunnel Freezers |

| Carton Freezers |

| Critical Process Air Handlers |

| freezon storage |

| fast cooling room |

| cold room |

| Very Large Capacity Low, Medium, or High Temperature Cold Storage |

| Low Temperature Cold Storage Warehouses |

| Grocery Distribution Warehouses (Standard or Penthouse Arrangement) |

| Blast Freezing Tunnels |

| fruit processing |

| fruit storage |

| vegetable processing |

| Loading Docks or Areas |

| industrial refrigeration plants |

| industrial cold room |

Lead Time: 10 - 20 days

Payment Terms: 30% T/T payment in advance, 70% T/T payment before delivery

Packing Condition: Standard export packing or customized packaging